Probably the largest and most significant project to have been developed at TCMS since its inception is founding member Erik Leonard’s electric motorcycle project. Erik has long been interested in alternative energy sources and projects, and after reading about various homegrown electric vehicle (EV) projects online, decided that he wanted to make his own. Due to cost, complexity, and physical size restraints, he decided to try building an electric motorcycle rather than a car. This was still a very challenging project for him in a number of ways, however, as he then had no motorcycle license or riding experience, and despite an extensive background in robotics had never attempted to build or significantly modify any kind of vehicle before.

Erik chose the fundamental components for the first iteration of his motorcycle based on a combination of practical, convenience, and aesthetic reasons. A close friend was willing to sell him a sport bike (Kawasaki Ninja) which he could use as a base platform for a reasonable price; this particular bike has a wide aftermarket for mechanical replacement and upgradeable components, and appealed to Erik’s aesthetic tastes. The Ninja also happened to have a spine or ‘backbone’ frame, which made swapping out the existing gasoline powertrain a relatively easy task and provided lots of flexibility for mounting EV components in different spatial configurations for optimal weight balance, ease of installation / maintenance, and overall design effectiveness. Erik’s online research into other EV projects provided him with a set of equations for calculating how powerful of a motor would be needed to drive the bike, based on the projected weight of the bike + rider, desired top speed, and overall performance characteristics, among other things; after running through the calculations and double-checking his work, he was able to easily obtain a suitable motor from an eBay vendor. His research also put him in direct contact with many other EV creators, one of whom sold him a motor controller sourced from another EV manufacturer (Zero Motorcycles). Finally, the first iteration of the motorcycle made use of secondhand lead-acid batteries purchased from Craigslist for the power source, for reasons of cost and easy maintenance (in terms of swapping individual cells out as needed).

After acquiring all of these major components and putting a lot of time and effort into creating electrical and mechanical designs / layouts for the motorcycle based on these components, Erik started assembling it at the Makerspace’s old facilities in Johnson City. He was able to assemble the motorcycle with relatively few problems due to the extensive design preparation performed ahead of time, although installation of the batteries proved problematic due to their weight and to tight spatial constraints within the square-stock metal frame he’d welded and installed within the Ninja’s existing frame to hold the new powertrain components. He also found that the motor’s wiring was reversed with respect to his expectations, causing the motorcycle to only work in reverse when first turned on. After correcting this and replacing a few defective battery cells, however, he had a working electric motorcycle which he could legally drive around town!

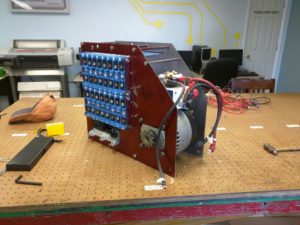

Following an initial shakedown period and a growing enthusiasm for the project, Erik elected to make several improvements to his motorcycle. First, the lead-acid batteries were replaced with lithium-iron-phosphate units, which provided a lot more energy storage and transmission capacity as well as a significant weight advantage, albeit with a considerably higher up-front cost than the lead-acid cells. He chose this battery technology over the more commonly known lithium-ion batteries for reasons of safety, as the phosphate units are less volatile in the event of a crash. These upgrades increased the effective top speed of the motorcycle from 45mph to 70mph, and provided a far greater operating range of 60 miles from the original’s range of 15 miles. Second, he replaced the relatively crude square-stock frame with one designed in CAD software and created with laser-cut panels, which gave more room for the powertrain components and was far better tailored to the Ninja’s existing frame, as well as providing significant weight savings over the old frame. These upgrades were performed at the Makerspace’s current facilities on State Street in downtown Binghamton.

Erik continues to ride this motorcycle whenever weather permits, and gets a great deal of satisfaction from the experience as well as from being able to apply the knowledge and skillset acquired from this project into many others! He is also turning this project into a business venture, working with a fellow TCMS member (Stephen Musok) to launch a “plug and play” EV powertrain module for use in other electric motorcycle retrofit projects. All of the digital design files associated with this project are open-source, so any Makers with the tools, skillset, and ambition can use them to make their own electric motorcycle if they want to; however, given the complexity and level of resources needed to build your own electric motorcycle from scratch, this may be very difficult for the average Maker. Erik wants to make the electric motorcycle retrofit process a relatively simple and more accessible one! He is currently exploring packaging options for the powertrain module to make it compatible with the frames of various other popular motorcycles, and (with Stephen) speaking with various local organizations regarding manufacturing and selling a few motorcycles based on his current designs. His project looks to have a bright future, and the Makerspace is proud to have provided it with a home during its genesis and subsequent modifications, and to have Erik as a member!

Based on an interview conducted with Erik Leonard on 3/10/2017. All photos in this blog post are the exclusive property of Erik Leonard, and are used here with his permission. For more information on the electric motorcycle powertrain retrofit kits, please visit http://www.nextwavemotors.com.